TopWell carwash

Drive Through Bus/Truck Wash Machine

- Up to 60 buses per hour cleaning capacity makes the drive-through bus wash machine the first choice for bus companies

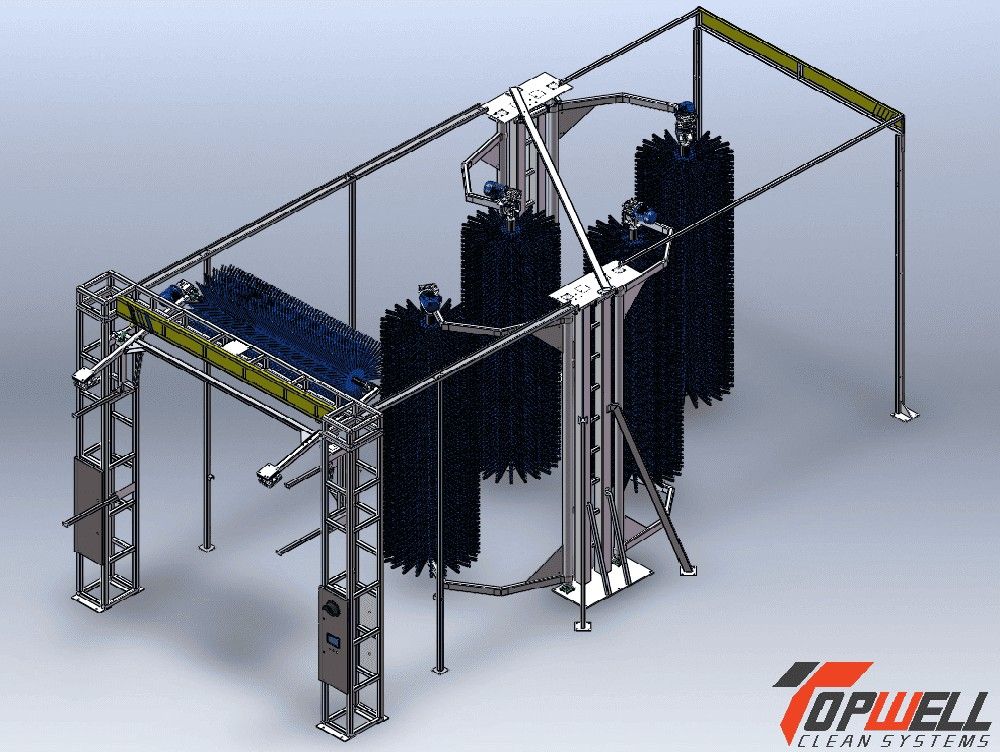

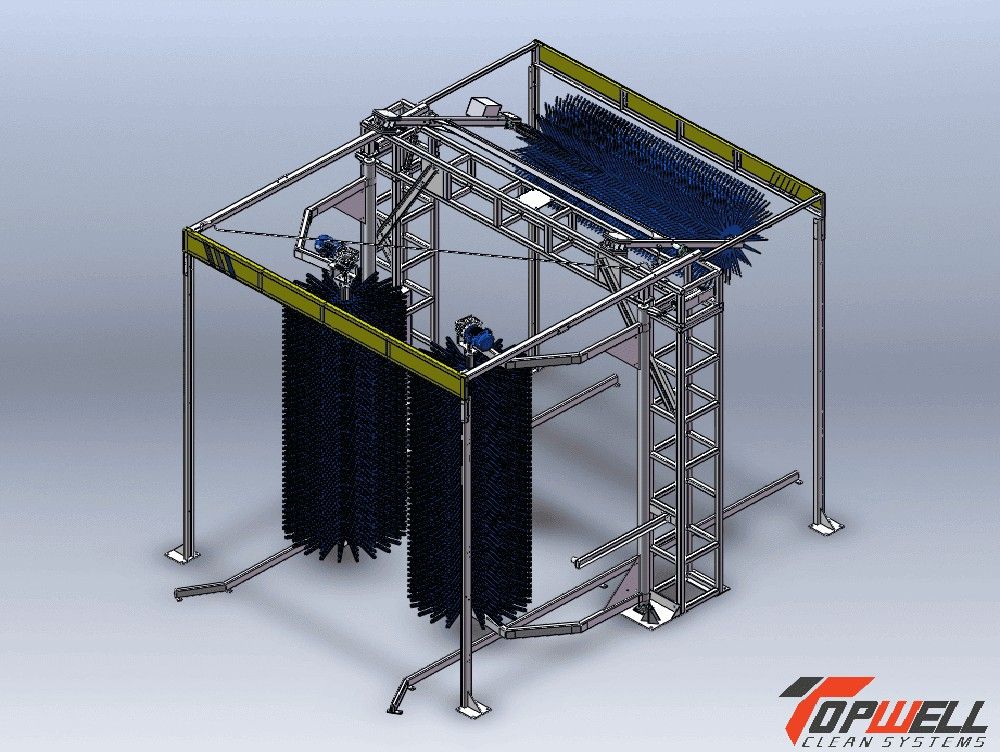

- 3/4/5/7 brushes available

- Support customization

Contact us for a price

Speak To A Car Washing Machine Specialist

Specifications

Drive Through Bus/Truck Wash Machine Details

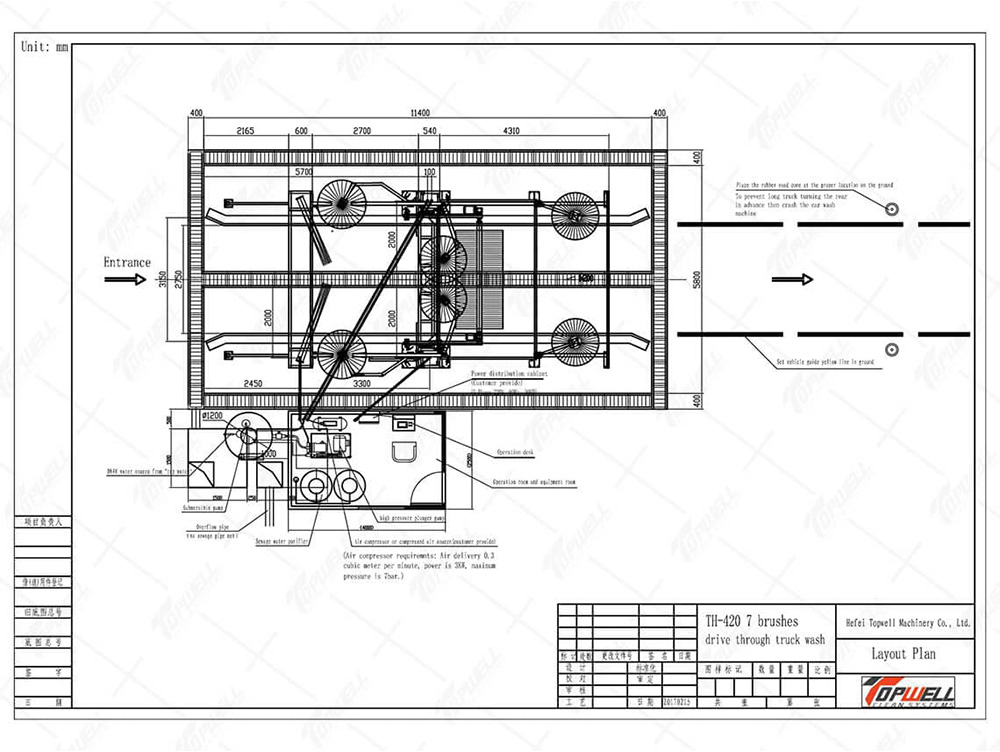

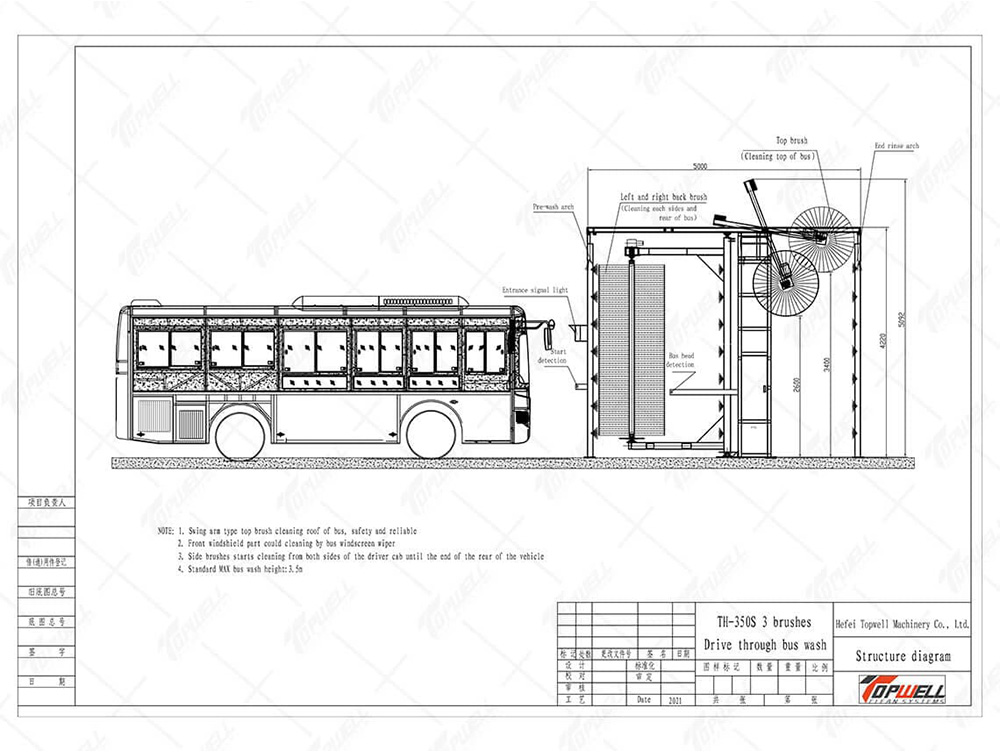

The drive-through bus wash machine TH-350 series is specially designed for bus, coach, and van trucks. Adopt drive-through type bus washing, the equipment is fixed on the ground, and the vehicle is driven into the machine by the driver at a uniform speed and slowly for a good cleaning.

The machine composed of a side/top brush mechanism, electric control system, pneumatic system, water supply system, detergent supply system, signal indication, and operating system, etc., automatically cleans the front, sides, and rear of the vehicle by spraying water, foam spray and brushes washing. Its biggest feature is continuous and quick washing, up to 60 vehicles per hour; Widely used in cities’ bus systems, truck fleets, tourist bus rental companies, and truck manufacturers.

| Model | TH-350 series |

|---|---|

| Equipment size (LxWxH) | Standard-5.8 x5.3 x4.22 m |

| Wash for | Bus, coach, and container truck |

| Max wash size | Standard-3.5m height Maximum can custom to 4.4m height |

| Wash capacity | 60-80 vehicles per hour |

| Machine total power | 12kw+ (depends on brush quantity) |

| Power supply | 380V, 50HZ, 3P. Accept customization. |

| Brushes | 3,4,5,7pcs brushes can be chosen |

| Water consumption | 150L per minute |

| Foam | Equipped |

| Machine material | Galvanization |

| Undercarriage cleaning | Optional |

| HP water cleaning | Optional |

| Dryer arch | Optional |

| Water recycling system | Optional |

Main Features

● According to the cleaning needs of users, there are 3, 4, 5, 7pcs brushes to choose from

● The cleaning height can be customized according to the customer’s highest vehicle

● Integral galvanized material, DuPont baking paint process, more corrosion-resistant

● Symmetrical side brush design, effectively avoiding the blind corner in the middle

● Original imported Italian bristles (FAVAGROSSA), wear-resistant, 4 times the service life of domestic products, and high cleanliness

● Drying arch is optional. The number of blowers can be selected, to solve the problem of freezing during car washing in cold areas in winter

● With the combination of automatic cleaning and manual control, it can safely avoid the attachments on the vehicle

● With perfect fault self-diagnosis function, display alarm record for fault type

● Equipment service life 19 years

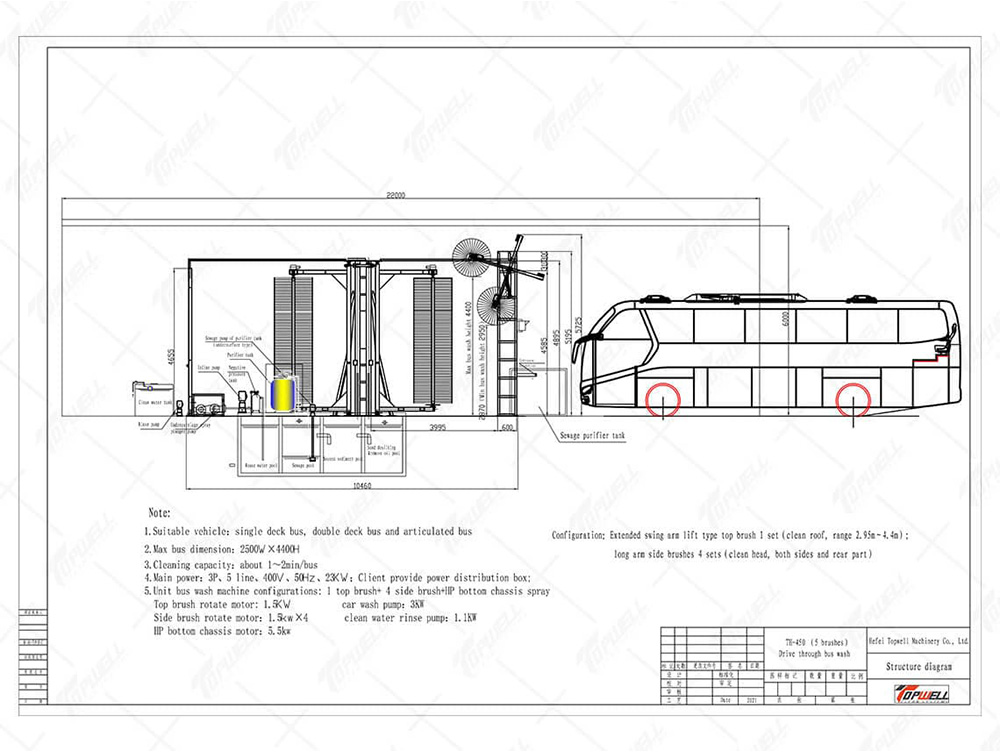

Frame drawing

The details you may care about

Washing video

Drive through bus wash

Trusted Clients

More and more clients choose to trust and cooperate with TOPWELL

Services

Customization Steps

Discuss Your Needs

Tailored Solution

Precision Manufacturing

Installation & Training

Contact us for a price

Speak To A Car Washing Machine Specialist

FAQ Guide

Drive Through Bus/Truck Wash Machine

How to solve the after-sales problem after the equipment is installed?

At present, WhatsApp and other foreign social media software cannot be opened in China without a VPN. Therefore, after cooperation, we suggest the customers download the WeChat App. Topwell will set up a separate group for each customer, which includes the salesperson and the technician in the factory. If you have any after-sales problems, you just need to describe the problem clearly and send relevant photos and videos to the group. Our technicians will guide you and provide a solution immediately.

My staff and I do not have any professional knowledge of equipment, how to manage and maintain it?

Except for the professional car washer agents that we cooperate with (acting for our brands and also for European and American car washer brands), it can be said that most of the other customers are the first time to come into contact with a fully auto car washer. Our equipment is actually very simple to maintain, and the operation manual also gives detailed regular maintenance instructions. For example: regularly apply engine oil to the chain, empty the air inside the compressor every day when the business is closed, wipe the surface of the sensor every day, and so on.

If the equipment fails, the touch screen will give an alarm record. The operator only needs to take photos of the faulty part and the alarm record. We may still need the signal light photo of PLC, after that, our technicians will give the troubleshooting method to find the problem and solve it. Every step is operated after our guidance, which is very easy to handle. And the equipment has high stability, so there is no need to worry about the failure rate.

How to get a truck wash solution?

1. Providing vehicle photos

2. Confirming maximum vehicle dimensions

3. How many vehicles need to be cleaned per day?

How long is the lead time?

Standard 380V, 50HZ, 3P required 50 days; Other voltage and frequency plus 10 days.