TopWell carwash

Auto Touchless Car Wash Machine

- 360° touchless type with HP under-chassis clean

- 100kg water pressure rinse

- Standardized LED lava foam

- 4/6pcs 5.5kw dryers available

- 3 years warranty

Contact us for a price

Speak To A Car Washing Machine Specialist

Specifications

Auto Touchless Car Wash Machine Details

WS700/800/900 series adopts an advanced intelligent ultrasonic detection system, accurate measurement of car width and length, collect full-body cleaning, wax coating, and protective paint in fine car washing equipment.

WS800 suspension equipment adopts a built-in without resistance hoisting type pulley, smoother light, and quiet during operation. Equipped with a standard servo motor and frequency conversion motor, to drive the horizontal, rotation before and back/forth operation, make the perfect mechanical structure and servo drive Cooperate well.

Relying on innovative design and operation, compared with WS700 or other models, the WS900 uses precise numerical control operation technology and an intelligent ultrasonic bilateral positioning system. Bilateral positioning technology could avoid barriers to solving the shortage of the triangle in the triangulation, and solve the problem of side washes difficult follow-up. The product also adopts Industrial timing belt technology to ensure the safety and accuracy of each step of the operation, thus greatly improving the cleaning effect of the equipment and reducing the failure of the equipment operation.

“L” type spray rod is made of 304 stainless steel to prevent rust and nozzle blockage. L-type spray rods not only can spray HP water but also can spray detergent under the same nozzle. In terms of the high and low-pressure liquid junction, Topwell adopts a non-power self-control valve, thoroughly solving the problem of frequent failures of electric and pneumatic valves.

About the dosing pump system, Topwell uses a 5-channel dosing pump to control the pre-soak foam, triple color foam, and Wax. Meet the different client wash needs and control the using cost more accurately

| Model | WS900 | |

|---|---|---|

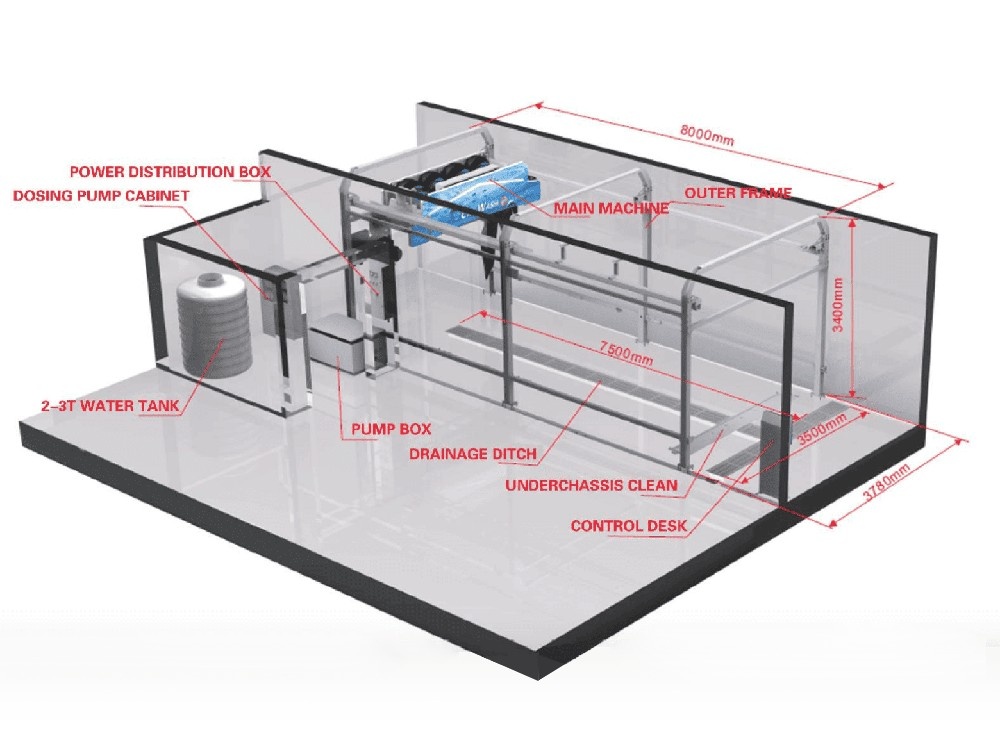

| Size | Standard Machine Installation Size | 8200*3800*3850mm (26.9ft *12.5ft *12.63ft) L*W*H |

| Max. wash car size | 6000*2400*2050mm (19.82*7.10*6.87ft) L*W*H | |

| Consumption per car | Foam consumption | Around 100ml/car |

| Water wax consumption | Around 20ml/car | |

| Water consumption | A/B/C/D wash program, 65-200L/car | |

| Electricity consumption | 0.8-1kwh/car | |

| Wash capacity | 7-15 cars per hour | |

| Specifications | Machine total power | 55KW |

| Power supply requirements | AC 380V/50Hz/3P/35KW, 16 square meters copper cable (ground wire and neutral wire both are 2.5 square meters) | |

| Air switch | 100A air switch (User provide) | |

| Water pump motor power | 18.5KW/100Bar working pressure, Max. 120Bar | |

| Fan motor power | 4pcs 5.5KW top dryers+2pcs 5.5KW side dryers | |

| Longitudinal motor power | 0.55KW asynchronous frequency control | |

| Transversal motor power | 1KW digital drive motor | |

| Rotary motor power | 1KW digital drive motor | |

| Chemical dosing pump | 0.37KW | |

| Central Processing Unit PLC | Industrial intelligent digital control system | |

| Drive system | Variable frequency speed control + digital driver | |

| Detection system | Intelligent three-dimensional detection system | Detect height, length and width |

| Sensing system | Ultrasound 4 sensors | |

| Touch screen | Delta brand | 10 inch |

| Packing details | Packing weight / Volume | 3.3Ton / 15CBM |

| Plywood case for water pump | 1300 × 830 × 600mm | |

| Plywood case for dosing pump | 1200 × 550 × 1250mm | |

| Wheel brush case | 2000 × 1000 × 1000mm (optional) | |

| Wheel brush | 700 × 400 × 400mm 2pcs (optional) | |

| Rails and frame | 2pcs (ometer and smeter) | |

| Language | Touch screen | English/Spanish/Korean/Russian |

| Voice broadcast | English | |

| Paper doc | English | |

4 Standard washing process

Wash program A: Undercarriage cleaning-pre wash-Tri-color foam-HP flushing-Foam rinse-HP flushing-Coated wax-Strong drying

Wash program B: Undercarriage cleaning- Tri-color foam-HP flushing

Wash program C: Foam rinse-HP flushing-Coated wax-Strong drying

Wash program D: Undercarriage cleaning-Tri-color foam-HP flushing-Coated wax-Strong drying

Main Features

● Intelligent fully-auto operating systems, 24h self-service card reader payment station

● Smart 360 technology for fast cleaning of every corner of vehicles

● Intelligent liquid proportioning system for spraying tri-color foam at the same time, shampoo,

wax rain on every corner of vehicles

● Innovative suspension system without resistance rails

● Unique embedded fast drying system, 6pcs 5.5kw top dryer

● Digital voice security alarm system

● Faulty self-checking system

● Auto collision avoidance technology

● One key anti-frozen system

● E-chain utility routing

● Staple open wash bay, customers entering easily

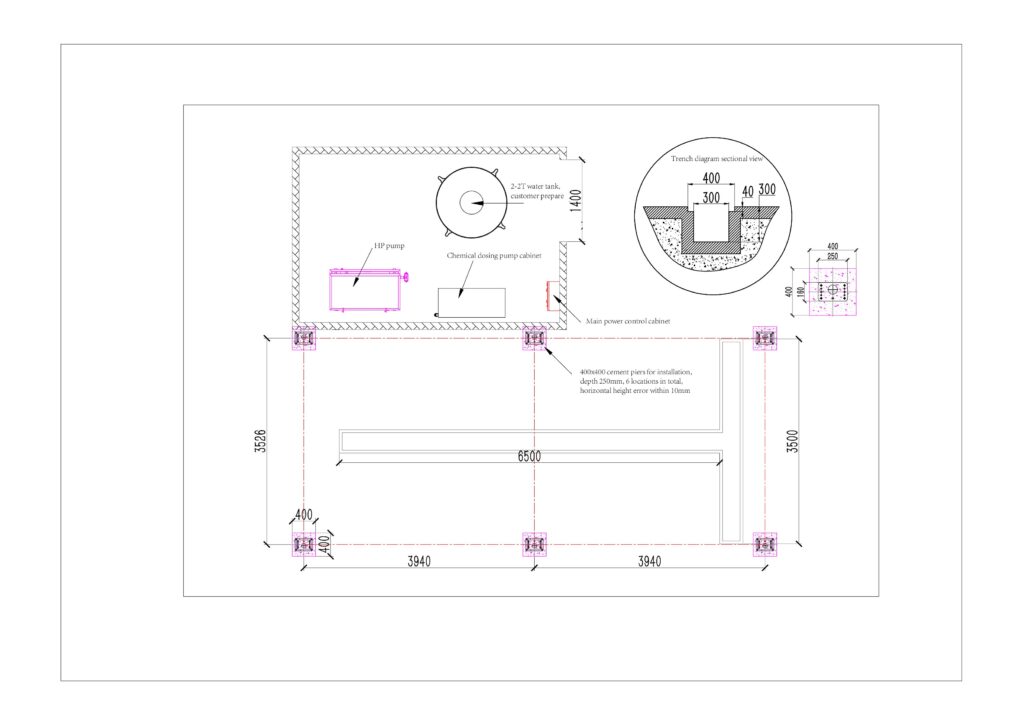

Frame drawing

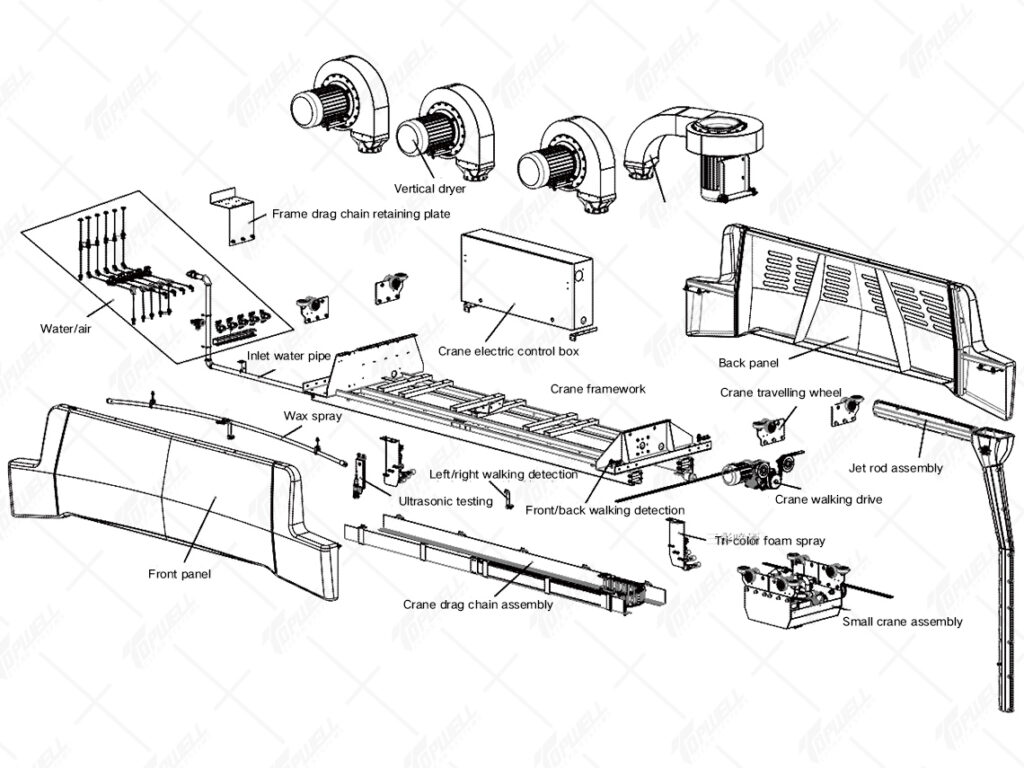

The details you may care about

Washing video

Single arm touchless car wash

Trusted Clients

More and more clients choose to trust and cooperate with TOPWELL

Services

Customization Steps

Discuss Your Needs

Tailored Solution

Precision Manufacturing

Installation & Training

Contact us for a price

Speak To A Car Washing Machine Specialist

FAQ Guide

Auto Touchless Car Wash Machine

How long is the machine warranty?

3 years after client receive the machine. Under the warranty period, factory bear the parts cost and domestic logistic fee, client should bear the international transport fee.

What are the advantages of Topwell compared with other car washing machine brands?

Brand advantage-Topwell’s cooperative factory is the leader in the car washing machine industry, specializing in the production of car washing machines. The equipment is optimal in terms of cleaning effect, stability, and failure rate.

Professional advantage-Topwell has been in the car washing industry since 2015 and has maintained a continuous and good cooperative relationship with the factory, which is equivalent to the factory’s export office. At the same time, grasp the current situation of domestic car washing machines, and know the advantages and disadvantages of each car washing machine factory.

Geographical advantage-The distance between Topwell and the factory only costs 1-1.5h, support factory inspection at any time.

Service advantage-Topwell partners actively break the concept of jet lag, stay online 24h, and provide customers with no-worry services

TOPWELL only supplies cleaning system products!

My staff and I do not have any professional knowledge of equipment, how to manage and maintain it?

Except for the professional car washer agents that we cooperate with (acting for our brands and also for European and American car washer brands), it can be said that most of the other customers are the first time to come into contact with a fully auto car washer. Our equipment is actually very simple to maintain, and the operation manual also gives detailed regular maintenance instructions. For example: regularly apply engine oil to the chain, empty the air inside the compressor every day when the business is closed, wipe the surface of the sensor every day, and so on.

If the equipment fails, the touch screen will give an alarm record. The operator only needs to take photos of the faulty part and the alarm record. We may still need the signal light photo of PLC, after that, our technicians will give the troubleshooting method to find the problem and solve it. Every step is operated after our guidance, which is very easy to handle. And the equipment has high stability, so there is no need to worry about the failure rate.

How long is the lead time?

Standard 380V, 50HZ takes 20 working days.