TopWell carwash

Auto Rollover Car Wash Machine

- 4 different wash programs to meet different cleaning needs

- Could connect with payment station to achieve non-human operating car wash shop

- Wash capacity 7-15 cars per hour

Contact us for a price

Speak To A Car Washing Machine Specialist

Specifications

Auto Rollover Car Wash Machine Details

The 7th-generation rollover car washing machine has 5 brushes and 4 dryers, including two EVA foam material side brushes, one EVA top brush, and two Italy FAVAGROSSA tire brushes. The top four 5.5KW fixed Q-type dryers reduce the failure rate when compared with old contouring dryers and greatly reduce the frequency of after-sales.

Two independent dosing pump systems control the functions of foam and wax water, can more accurately control the amount of the detergent, and wash one car by only consuming around 10ml of detergent.

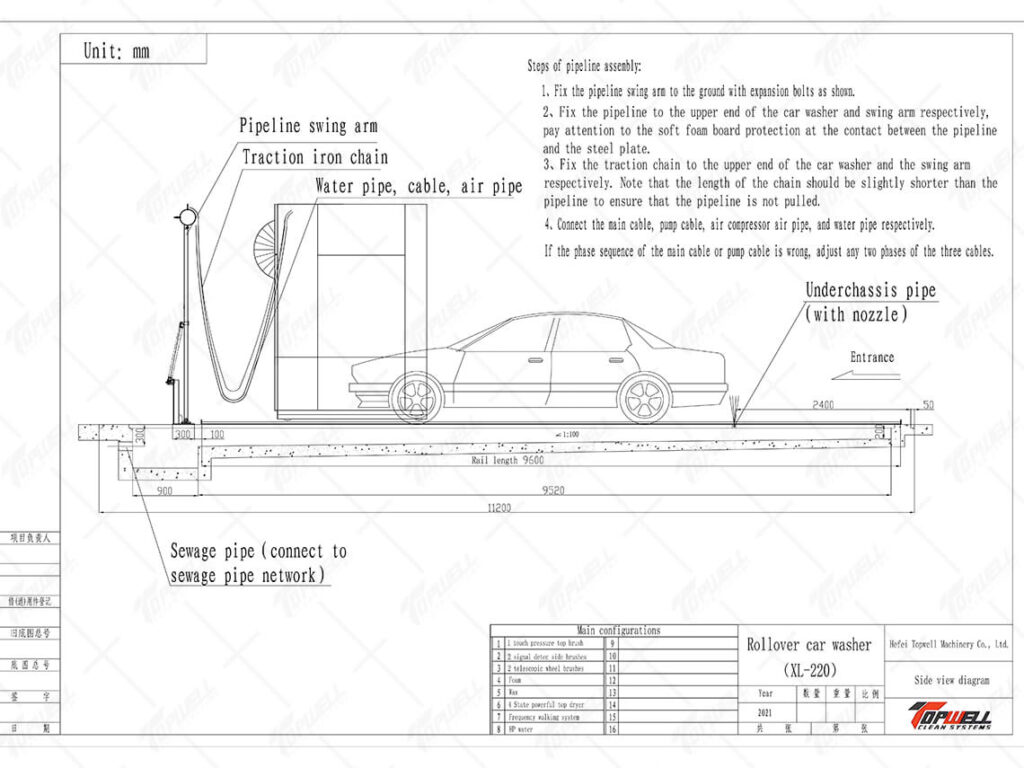

4 cleaning procedures provide customers with diversified cleaning options, with a cleaning speed of 7-15 vehicles per hour. In addition, the main advantage of the rollover car wash type is to save space. It only needs 11 meters long and 5 meters wide to install one, which is very good for customers who want to invest in a car washing shop with insufficient space but a good location.

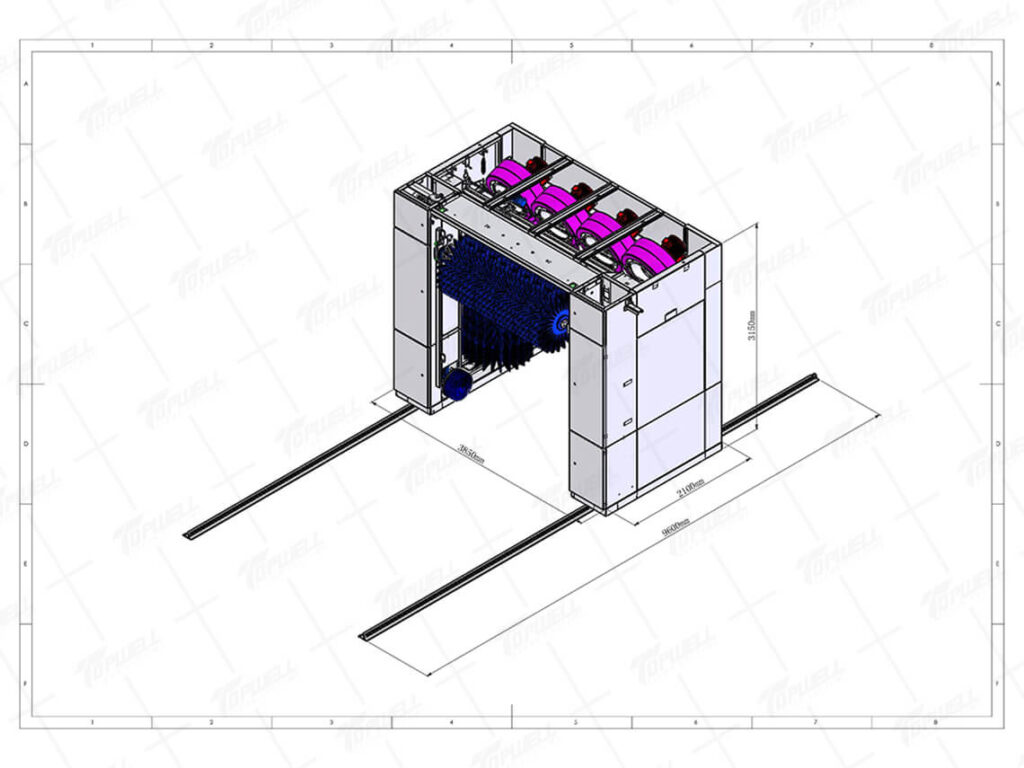

| Model | XL-220 |

| Machine size | 2100*3850*3150 (L*W*H mm) |

| Rail length (mm) | 9600. Accept custom. |

| Min installation size (mm) | 11200*5000*3350 |

| Wash for | Cars, SUVs, and Pick-ups |

| Max wash size | 5700*2200*2200 (L*W*H mm) |

| Brush | 2 vertical side brushes, 1 top brush, 2 Italy wheel brushes |

| Dryer | 4pcs*5.5kw |

| Power | 25kw, 380V, 50HZ, 3P. Accept custom. |

| Air supply | Pressure >7kg/m² |

| Water supply | DN25 |

| Water consumption | 80-100L/car |

| Electricity consumption | 0.5kw/h/car |

| Detergent consumption | 10-13ml/car |

| Undercarriage cleaning | Optional |

| HP water rinse | Optional |

| RO water (Spot-free) | Optional |

| Water recycling system | Optional |

Main Features

● The whole machine is galvanized, with DuPont baking paint process, more corrosion-resistant and durable

● Choose well-known brand electronic components to improve the safety and stability of equipment operation

● Use EVA foam material cleaning car body brushes, with high cleanliness, and strong anti-aging ability. In the meantime, the smooth surface does not stick sand so will not scratch the car paint during the rotation

● High-definition 10’ touch screen, real-time display of equipment operating status, with vehicle detection device, can indicate the driver’s parking status

● One-key shielding of fault points to realize emergency car wash function, do not need to worry one component is broken and affect the next car washing

● Car wash counting function, realizing year, month, day, and total statistics

● Controlled foam and bright wax system by 2 dosing pumps, accurately control the cost of consumables

Frame drawing

The details you may care about

Washing video

Gantry type rollover car wash test before the delivery

More Options

Optional functions or configurations can be achieved on your rollover car wash

Standardized car washing machines may not be able to meet customers' local consumer market and cleaning habits, so TOPWELL can also customize equipment for customers, as long as your idea is feasible in our opinion and will not affect the stability of the equipment, then we can completely follow your idea and customizing the car washing machine belongs to your car wash shop.

High-pressure water

Tri-color foam

Spot free water rinse

Water recycling system

Trusted Clients

More and more clients choose to trust and cooperate with TOPWELL

Services

Customization Steps

Discuss Your Needs

Tailored Solution

Precision Manufacturing

Installation & Training

Contact us for a price

Speak To A Car Washing Machine Specialist

FAQ Guide

Auto Rollover Car Wash Machine

Q1: How to solve the installation problem?

We can send 1 engineer abroad for installation, and at least 2 workers are required to assist on the installation site. All costs during the installation period are borne by the customer, including: visa fees, local accommodation, insurance, round-trip air tickets, and a daily allowance of 200 USD per engineer per day.

Q2: How to solve the after-sales problem after the equipment is installed?

At present, WhatsApp and other foreign social media software cannot be opened in China without a VPN. Therefore, after cooperation, we suggest the customers download the WeChat App. Topwell will set up a separate group for each customer, which includes the salesperson and the technician in the factory. If you have any after-sales problems, you just need to describe the problem clearly and send relevant photos and videos to the group. Our technicians will guide you and provide a solution immediately.

Q3: How long is the machine warranty?

The equipment warranty become effective after the delivery and warranty time is 2 years. In the first year, factory will bear the parts and logistic fee, for the second year, factory will bear the parts cost and client handle the international logistic fee.

Q4: How long is the lead time?

Standard 380V, 50HZ takes 30 days; The non-standard voltage needs to add 10-15 working days on the basis of the above, and all electrical components need to be customized by the manufacturer.

Q5: What about the payment term?

T/T in advance or L/C at sight can be negotiated