TopWell carwash

Auto Tunnel Car Wash Machine

- Up to 60 cars/h wash capacity can meet your car wash shop with over 500 cars washing daily.

- Different tunnel configurations meet different land sizes and budgets.

- Support customization on car wash functions

Contact us for a price

Speak To A Car Washing Machine Specialist

Specifications

Auto Tunnel Car Wash Machine Details

Among the many models of car washes, the high efficiency of the tunnel car washing machine makes the customer much loved.Under the condition of continuous washing, it can wash 50-60 vehicles per hour.The type of car is not affected.Cars, SUVs, and pickups can all be cleaned by a tunnel system.It is suitable for car wash shops with a daily cleaning capacity of more than 300 vehicles.

Widely used in : car dealer shops, auto repair shops, gas stations, highway intersections, large parking lots, and intersections with heavy traffic.

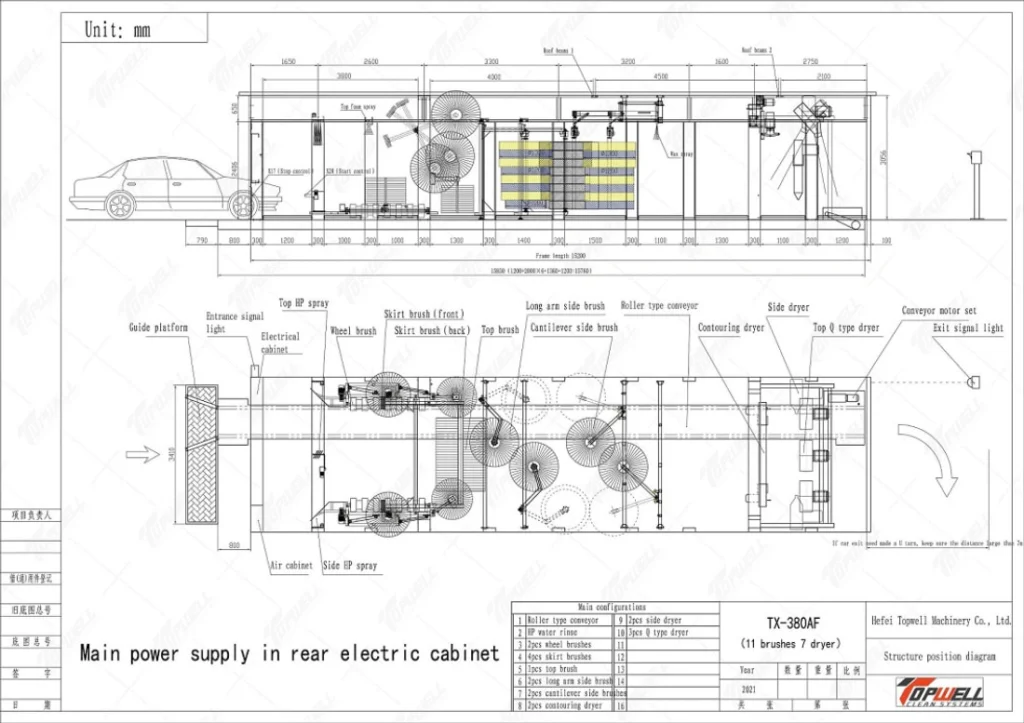

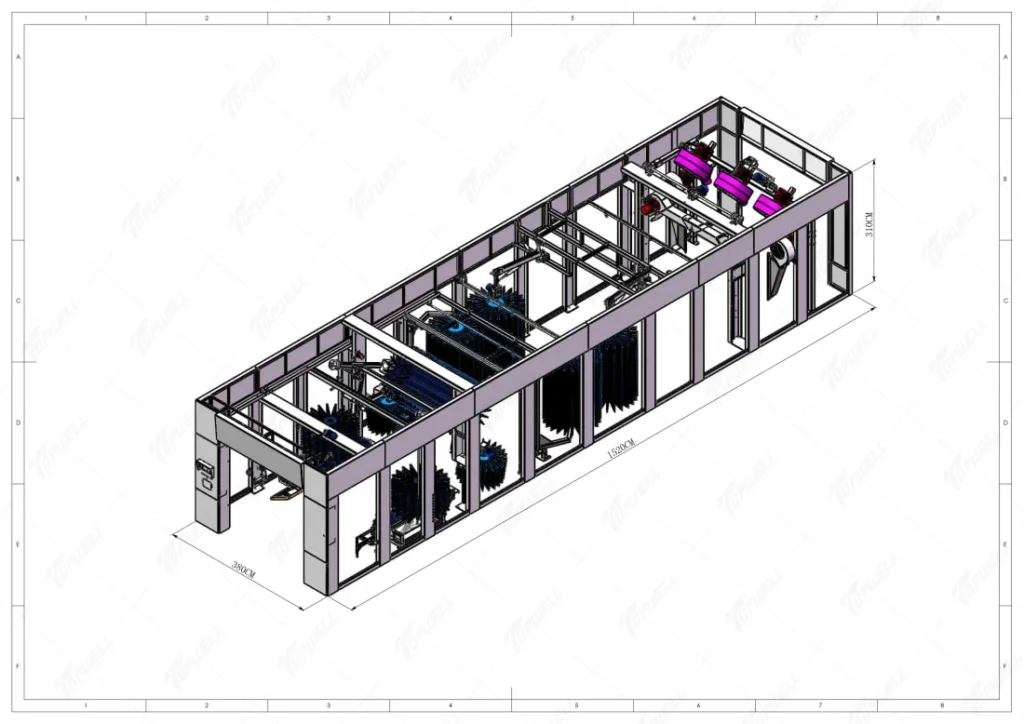

In order to meet the requirements of different customer sites and budgets, 5 standard models provide a variety of options. The number of brushes and the number of blowers determines the length and price of the equipment. As far as the export market is concerned, the 11-brush model has the highest sales because which equipped with two horizontal Italian FAVAGROSSA brand wheel brushes. Please check the parameters of the 5 models below.

| Item | TX-380AF | TX-380A | TX-380BF | TX-380B | TX-380G |

|---|---|---|---|---|---|

| Brushes and dryer | 11 brushes 7 dryer | 11 brushes 4 dryer | 9 brushes 7 dryer | 9 brushes 4 dryer | 7 brushes 4 dryer |

| Frame size, L*W*H (cm) | 1520*380*310 | 1360*380*310 | 1280*380*310 | 1115*380*310 | 1035*380*310 |

| Conveyor length (cm) | 1576 | 1420 | 1336 | 1176 | 1094 |

| Guide platform width (cm) | 79 | ||||

| Min Installing size, L*W (cm) | 2400×500 | 2200×500 | 2120×500 | 1960×500 | 1880×500 |

| Max wash size, W*H (cm) | 200×200 | ||||

| Max car wheelbase (cm) | 330 | ||||

| Power standard | 380V, 50HZ, 3P. Accept custom. | ||||

| Total power | 55KW | 35KW | 55KW | 30KW | 30KW |

| Water supply tube | DN40 | ||||

| Water consumption | 160 L per car | ||||

| Electricity consumption | 0.8kw/h/car | 0.8kw/h/car | 0.8kw/h/car | 0.5kw/h/car | 0.5kw/h/car |

| Wash speed | Up to 60 CPH | ||||

| Italy wheel brush | 2 | 2 | 2 | 2 | 2 |

| Short skirt brush | 4 | 4 | 4 | 4 | 2 |

| Top brush | 1 | 1 | 1 | 1 | 1 |

| Big side brush | 2 | 2 | 2 | 2 | 2 |

| Wrap-A-Round side brush | 2 | 2 | 2 | 2 | 2 |

| Contouring dryer | 5.5kw*2pcs | 5.5kw*2pcs | 5.5kw*2pcs | 5.5kw*2pcs | 5.5kw*2pcs |

| Side dryer | 3kw*2pcs | 3kw*2pcs | 3kw*2pcs | 3kw*2pcs | 3kw*2pcs |

| Top USA-type Q dryer | 5.5kw*3pcs | / | 5.5kw*3pcs | / | / |

| HP water | 550 psi | ||||

| Water pump | 70 psi | ||||

| Foam system (by dosing pump) | 1 | ||||

| Wax system (by dosing pump) | 1 | ||||

| Signal light | 2 | ||||

| Undercarriage cleaning | Equipped, with 5pcs nozzle | ||||

| Water recycling system | Optional | ||||

| Roof-Color steel plate | Optional | ||||

| Side glass-10mm thickness | Optional | ||||

Main Features

● The whole machine is galvanized, with DuPont baking paint process, more corrosion-resistant and durable

● Adopt advanced technology, and modular design, which can be combined according to different needs

● Import electrical components from well-known foreign manufacturers to ensure safety and reliability, also use own design parts to make sure suitable for car washing machine running

● Real-time fault self-detection system

● The use of high-grade car wash special brush, EVA foam material unstick sand to protect car paint. Longer lifetime can meet washing 900000cars

● If the machine will be installed outdoors, each side of the frame could mount glass, attracting clients to watch the washing process from the outside

● Mirror surface stainless steel guide mirror on the entrance, it safer to put the wheel on the conveyor and enter the machine

● High-brightness 10’ touch operation display screen, different languages can be supported

● HP water pre-washing system is standard for the whole series, rinse off the mud and sand on the car body before brush cleaning

● Complete data statistics, record daily car washes and total car washes

● Real-time fault shielding system, one-key shielding of fault points, reducing maintenance waiting losses

● Optional maintenance-free conveyor system, the vehicle conveying mechanism is more stable and longer life

● The new Q-type powerful air drying system can choose fixed, swing, and tracking mode

Frame drawing

The details you may care about

Washing video

Express tunnel car wash in Japan

More Options

Optional functions or configurations

Standardized car washing machines may not be able to meet customers' local consumer market and cleaning habits, so TOPWELL can also customize equipment for customers, as long as your idea is feasible in our opinion and will not affect the stability of the equipment, then we can completely follow your idea and customizing the car washing machine belongs to your car wash shop.

Precision Pre-Washing Solutions

Enhanced Visual Appeal with Lava Foam

Tailored Tunnel Structures for Global Markets

Spot-Free Cleaning with RO Water Systems

Eco-Friendly Water Recycling Systems

Trusted Clients

More and more clients choose to trust and cooperate with TOPWELL

Services

Customization Steps

Discuss Your Needs

Tailored Solution

Precision Manufacturing

Installation & Training

Contact us for a price

Speak To A Car Washing Machine Specialist

FAQ Guide

Auto Tunnel Car Wash Machine

Q1: What is an Auto Tunnel Car Wash Machine?

A: An Auto Tunnel Car Wash Machine is a fully automated tunnel-style vehicle cleaning system. It uses a conveyor belt to move vehicles steadily through an enclosed washing tunnel, completing the entire process—pre-rinsing, foam application, high-pressure water jets, brush scrubbing, waxing, and blow-drying—without manual intervention. Ideal for high-efficiency car wash demands at gas stations, parking lots, and similar settings.

Q2: What advantages does the Auto Tunnel Car Wash Machine offer over traditional car washing?

A: This machine integrates smart sensing systems and modular design, delivering three core advantages: 1) 300% higher efficiency, processing 500+ vehicles daily; 2) Reduces water consumption by over 40% with a built-in water recycling and purification system; 3) Supports customizable programs (e.g., undercarriage cleaning, coating care). Its flexible brushes and contour-following spray arms adapt to sedans, SUVs, and other vehicle types, eliminating scratch risks.

Q3: Will the Auto Tunnel Car Wash Machine damage vehicle paint?

A: No. Equipped with high-precision pressure sensors and contactless safety systems, the machine uses anti-static microfiber brushes and dynamically adjusts spray arm pressure. Combined with 360° contour-tracking technology, it ensures thorough cleaning while preventing surface scratches. SGS-tested and certified, it complies with ISO 9001 safety standards for vehicle surface care.

Q4: How to maintain the Auto Tunnel Car Wash Machine?

A: The machine features a self-diagnostic alert module and cloud-based remote monitoring for consumables (e.g., brush wear, filter lifespan). Routine maintenance includes weekly sediment tank cleaning and monthly replenishment of specialized detergents. Annual servicing covers lubrication of the drive system and sensor calibration. The companion app provides maintenance reminders, reducing unexpected breakdown risks by 90%.